The underground environment is unique with the unusual combination of muddy roads with dust-filled air. That makes it especially frustrating because your only recourse is more water. Unfortunately, that doesn’t help, creating even more mud.

The dust may be the enemy, but the water’s a close second, making the underground mine one of the toughest work environments possible.

There has to be a better way and there is.

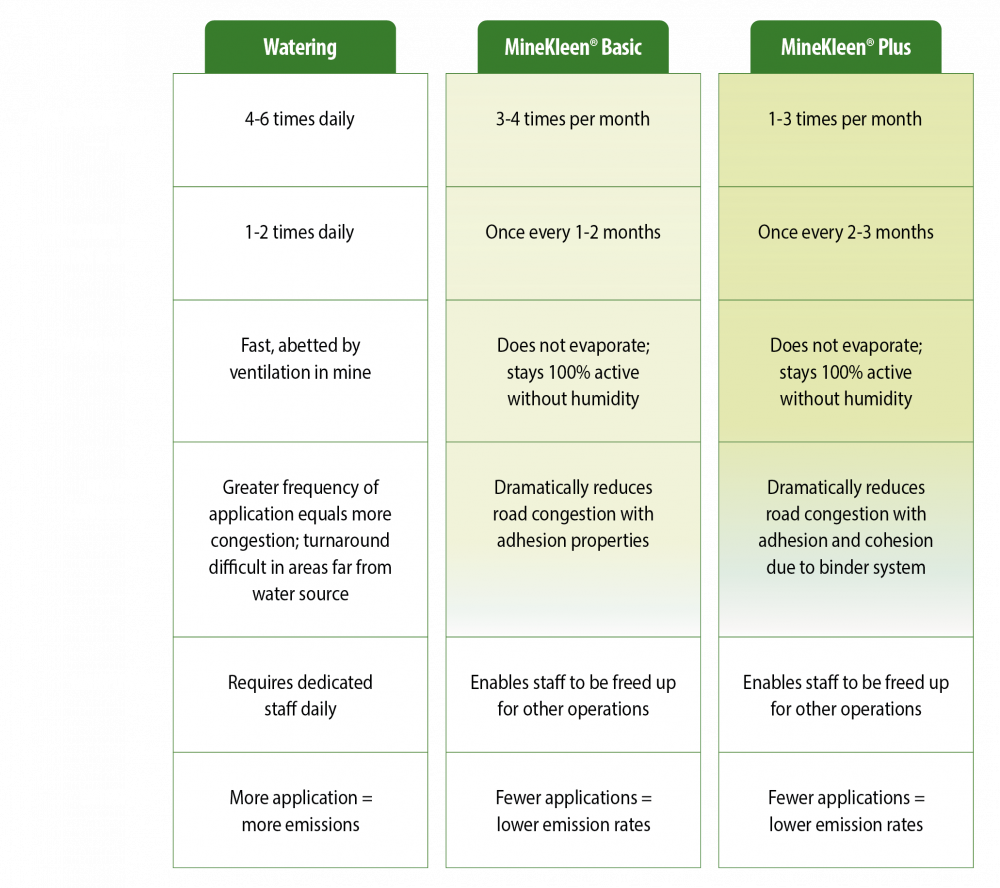

Midwest has taken on this challenge — not with water and the constant stoppages for endless reapplications — but with advanced chemistry and advanced technology in a program created specifically for your most extreme dust control in underground mine situations. Our solution eliminates both the dust and the mud. Now miners can have clean air and clear roads for better health and safety as well as optimum production.

Virtually eliminate dust now, with another new innovation from the industry leader.

Midwest has invented a complete system to almost completely wipe out dust, using the ultimate combination:

The MineKleen® Underground Mine Dust Control System

MineKleen® Formula

+

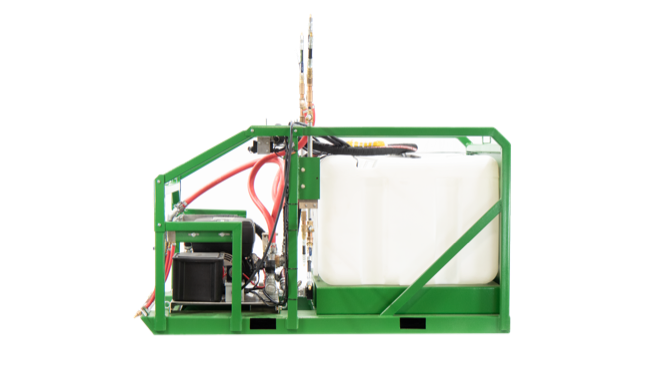

MineKleen® Sprayer

+

Step-by-Step Instruction Video

+

Easy-to-Read User Manual

+

Technicians Available for Training, Field Support, Service